How to Accomplish Optimal Product Flow for Your Gravity Conveyor

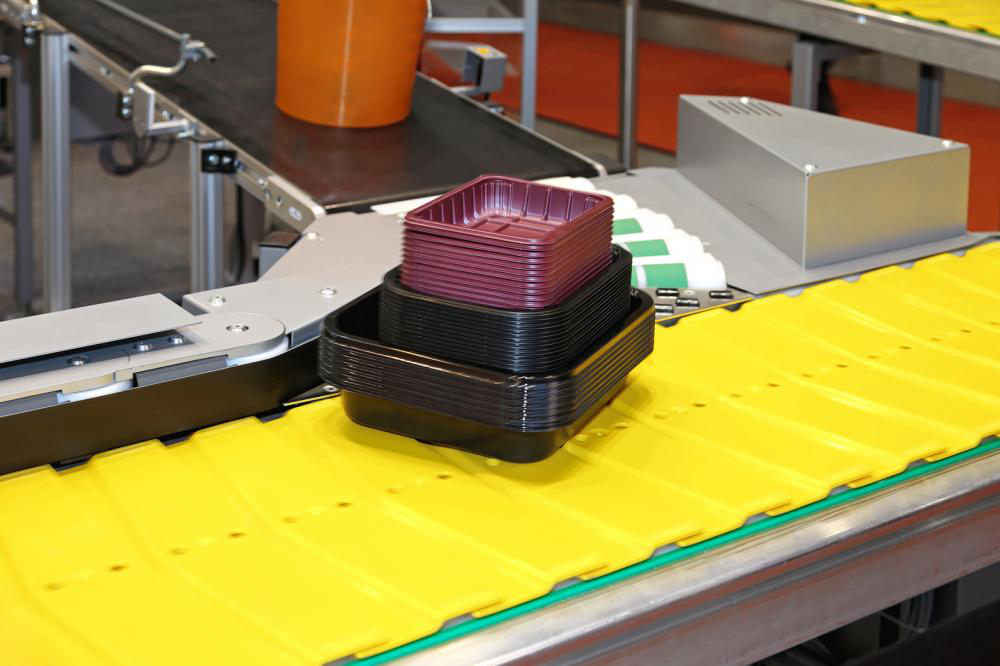

Gravity conveyors are among the most powerful material handling tools used by both small and large sized operations. Usually installed on a decline, these conveyors utilize the slope of the conveying line to move products quickly, efficiently and economically from one location to another.

The success of any gravity conveyor project depends on ensuring that the conveyor is set up the right way to accomplish optimal product flow. However, this is much easier said than done. Many times, facility owners aren’t simply aware of the strategies required to accomplish this objective, which somewhat limits the operational potential of their investment.

This article shares a few key recommendations for setting up your gravity conveyor for optimal product flow.

Specify for steeper gradient

The gradient of a gravity conveyor is controlled by adjusting the heights of the infeed and discharge terminals of the conveyor. By specifying a conveyor with an elevated infeed and a demoted discharge terminal, you can design a conveyor with a steeper gradient. This way, you can accomplish faster product flow for your facility. Keep in mind, however, that you don’t want the gradient to be too steep as it can damage the load during the conveying process.

Design for longer and straighter conveying line

Another way to accomplish faster product flow is to set up the gravity conveyor with a longer conveying line. Loads on longer conveying lines tend to flow faster than loads on shorter conveying lines. Also, try to avoid curves or turns and keep the design of the line as straight as possible.

Customize for load weight

It’s also important to customize your conveyor so that it fits the weight of your load. A conveyor improperly specified in terms of load weight can make your products move too slow, which can affect the productivity of your operations. Typically speaking, heavier loads always move faster than lighter loads on the same conveyor, at the same gradient.

Closing words

Always test your gravity conveyor for product flow before going live. It’s relatively easy to make adjustments to a conveyor before it goes into operation than when it’s already live and running.

KD Equipment is your one-stop shop for everything material handling. We sell a complete range of industrial material handling equipment—including gravity conveyors—to businesses in Florida. Visit our online product section to view our complete product catalogue.