Belt conveyors are an excellent choice foran inexpensive and simple method ofmoving products from one point to another.Because of the simplicity of the flat,moving belt, they can be used to move avariety of product sizes, shapes andweights effectively for long lengths with asingle drive. Belt Conveyors are also agreat option to move products throughelevations. Incline Belt Conveyors from lowto high and Decline Belt Conveyors fromhigh to low.

Request a Quote

CONVEYORS

CONVEYORS

KD Equipment offers a wide range of conveyors from trusted manufacturers that’s just right for you. This is a perfect solution for moving products faster and efficiently while addressing employee safety. And many models can ship in 24 hours. • Warehousing & Distribution, Order Fulfillment, Aerospace, Government Military & Agency, Automotive, Parcel Handling, Appliance, Cabinetry & Furniture and Food & Beverage

BELT CONVEYOR

BELT ROLLER CONVEYOR

GRAVITY ROLLER

Gravity Roller Conveyor is used to carry lightweight

packages or when operation requires lightweight

sections. Useful in setting up permanent or

temporary conveyor lines in warehousing activities,

shipping departments, assembly areas, etc.

LINE SHAFT CONVEYOR

These systems are primarily suitable for lighter loads. The

Line Shaft Conveyor is a quiet and efficient live roller

conveyor system. Each roller is powered individually by

spools, which in turn are connected fully by a composite “O”

ring or band. Perfect for large, long systems that can be run

with a single drive shaft which includes: curves, pop-up

transfers or spurs.

ZERO PRESSURE ACCUMULATION

Zero Pressure Conveyor will use a type of sensor

to segregate the conveyor into various sized

zones that will accumulate your product. The

most common of zero pressured conveyors, uses

rollers for transport of containers while using a

retro-reflective photo-eye to accumulate

products into zones.

VERTICAL RECIPROCATING CONVEYOR

VRC transport materials of all shapes, sizes, and weights

between two or more levels. Not designed for people or

operators. They are ideally suited for the safe and

efficient move of materials to a mezzanine, rack storage

system with catwalks, or any new or existing upper floor

level.

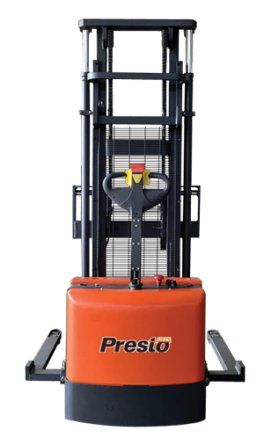

PALLET STACKER

Pallet Stackers are designed to stack pallets on

low, medium, or even high areas, such as

warehouse racks. Similar to Pallet Jacks or

Pallet Trucks, Stackers come in manual or

electric models and utilize hydraulics to easily

manipulate the height of the forks.

PALLET STACKER CONVEYOR

Pallet stacker/de-stacker provide an automatic method

of dispensing or accumulating empty pallets into or

removed from a conveyor system.