How to Mitigate Risk in the Warehouse

Every year, warehousing enterprises in the Unites States lose millions of dollars due to unforeseen risks. Natural disasters such as floods, and issues such as product damage and employee theft cost distribution companies billions of dollars.

When the operations of an enterprise involve the use of a warehouse or a storage facility, it’s vital to perform a careful assessment of all associated potential risks. This will help reduce the likelihood of incidents, and lessen their severity even if they do occur. Failure to do so will leave the facility vulnerable to heavy losses which can have a detrimental effect on the organization’s performance.

Below is a list of major risks to consider when evaluating risk in a warehouse.

Fire

Typically, warehouses are large cavernous facilities that are packed tightly with stored goods. This means that even a small fire can prove to be highly destructive. Apart from the obvious product damage, fire can lead to employee injuries and structural damage.

However, there are numerous effective measures that can be taken to mitigate the risk of warehouse fires. They include:

·Installing fire suppression mechanisms such as smoke detectors, sprinklers, extinguishers and fire doors

·Perform regular maintenance of fire detection mechanisms

·Ensuring that the facility is in compliance with current building safety codes

·Training workers to practice fire safety

Flooding

Flooding is another common warehouse risk, particularly in areas such as Florida, which are highly-susceptible to natural disasters. Floods not only pose a risk to the inventory, but it also pose a risk to the structure of the warehouse itself. Here are the preventative measures you can take to mitigate the risk of flood damage in your warehouse:

·Regularly conduct flood risk assessments to identify the areas that are particularly vulnerable to flood damage

·Install removable or permanent barriers in the openings of the facility to prevent flood water from entering the building.

·Ensure that electrical sockets and outlets are installed above ground level so they’re clear of possible flood water.

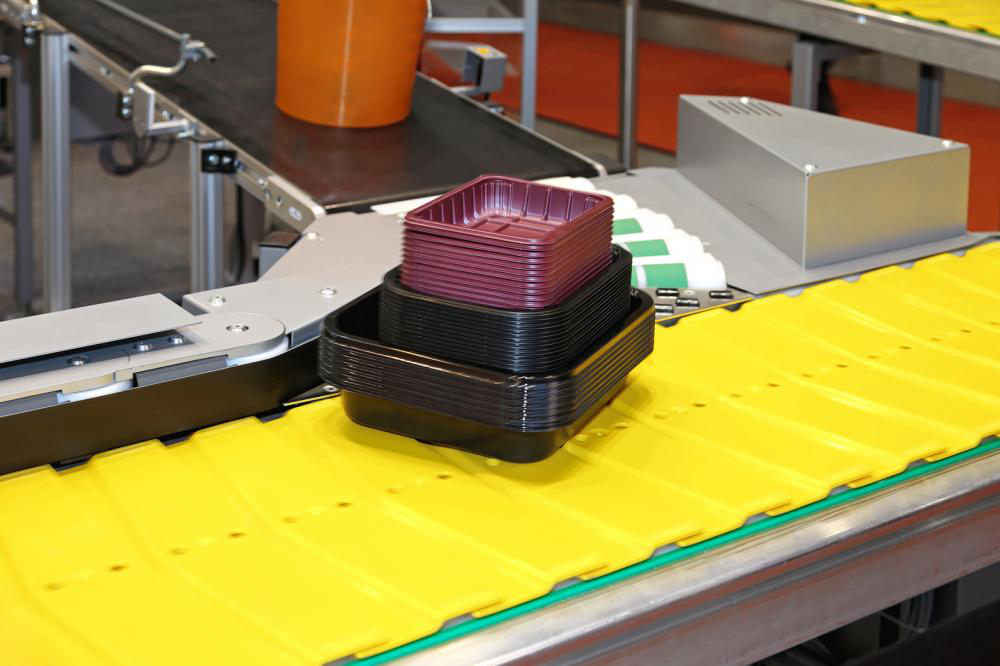

Loading Dock Safety

In most warehouses, the loading dock is the central hub of operations. Loading dock operations generally involve the use of heavy machinery such as forklifts, dock levelers , etc, which increase the likelihood of accidents and mishaps. These following preventive measures can be taken to mitigate the risk of loading dock accidents:

·Ensure that the load you place on the dock plate doesn’t exceed its load capacity

·Make sure the movable dockboards are secured in position so they don’t slip

·Make sure the trailer wheels are secured into position before you start loading or unloading.

With over three decades of experience in providing high-quality warehouse solutions, KD Equipment is one of the biggest names in the warehouse equipment industry. Based in Florida , we provide a wide variety of warehouse equipment including HVLS fans , air doors , and loading dock accessories. Get in touch with us for further information.