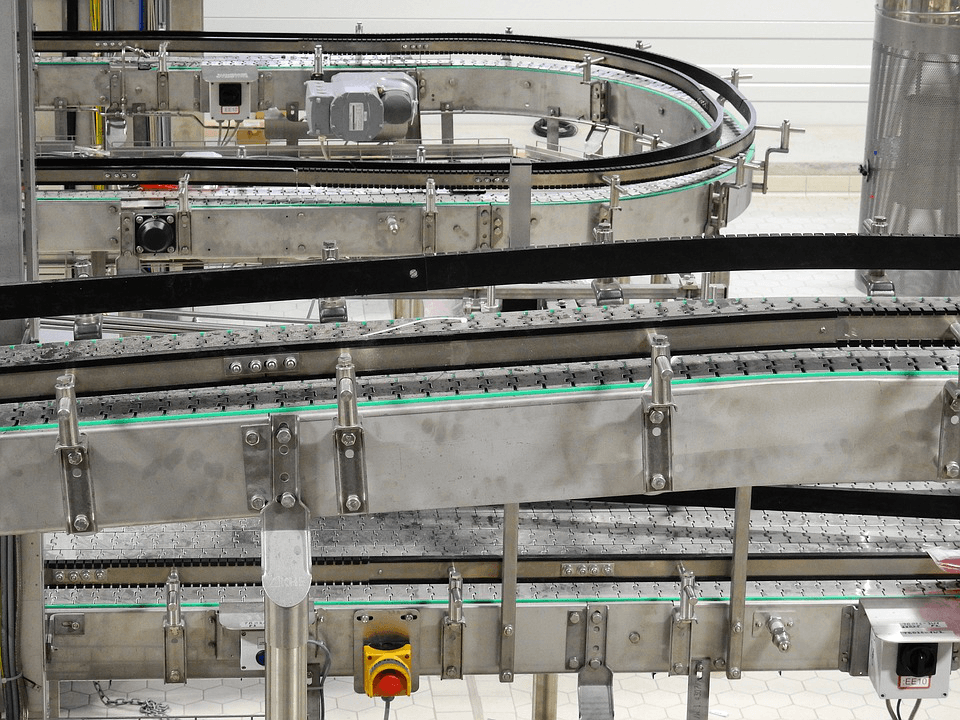

Is It Time to Reconsider Your Old Conveyor and Replace It?

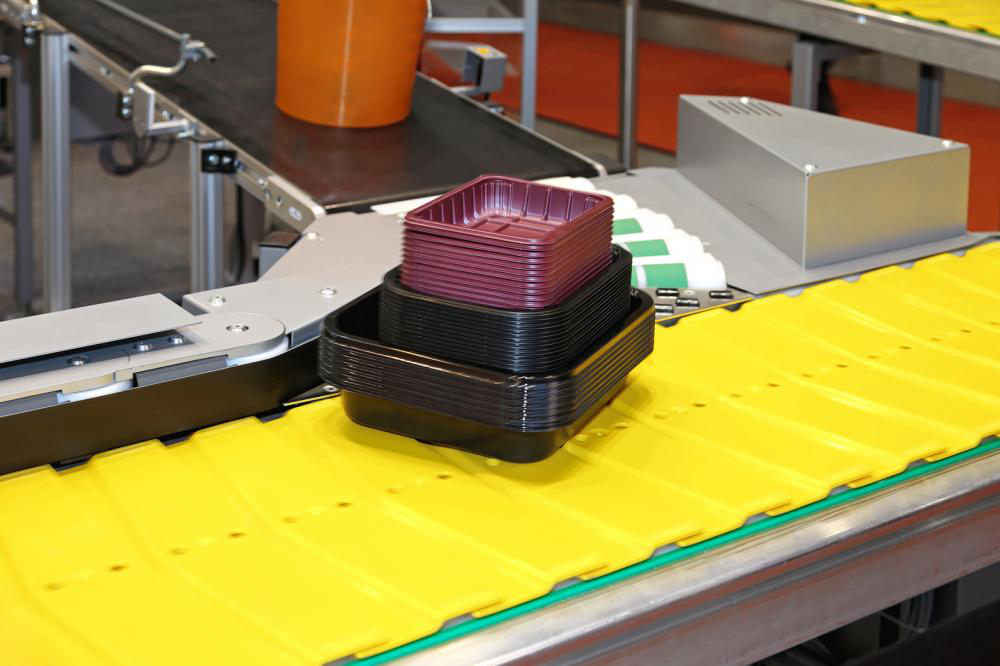

Conveyors are dream machines for warehouse operators. They take operational productivity to the next level, significantly improve worker efficiency, and tirelessly run for years, generating excellent return on investment. But they are machines in the end. And like every machine, they need to be replaced at some point. The challenge for facility owners then lies in accurately determining when to replace an old conveyor, especially when there’s still life left in the old dog.

If you too are contemplating over this question, but can’t decide whether this is the right time to replace your old conveyor or not, look for the following four sure signs of conveyor replacement to clear up any confusion:

1. You Conveyor Has Become a Constant Source of Maintenance and Repair

Initially, the unscheduled repairs were far and few to encounter, but now they pop up every so often. Sometimes, it’s the motor, sometimes the chains, and at other times, premature belt failures. Your team has grown frustrated and these frequent breakdowns are costing your business big time.

2. Spare Parts Have Become Increasingly Difficult to Find

You really have to search the market hard to find spare parts for your conveyor. In fact, sometimes the parts aren’t available at all in the local market, and you have to import them from other countries. The situation is getting worse day by day.

3. You Have Shifted to a New Product and the Design of the Product is Affecting Your Conveyor Efficiency

You just had to take this decision forced by competition and industry demands. But now that you have shifted to a new product, you’re realizing that your old conveyor configuration is struggling to adapt to the change. Your warehouse productivity has taken a major dip, and your employees are finding it hard to operate the conveyor efficiently.

4. You are Clearly Being Held Back by an Outdated Conveyor Technology

Your conveyor is quite old in terms of technology and that old technology is hitting your business with opportunity cost. You know you can sort and process more units in less time, cut down your electricity bills and further improve work ergonomics, but the outdated conveyor technology may be stopping you from doing all this.

So, does your old conveyor need replacing?

KD Equipmentcan assist you in your conveyor replacement project.

We stock a large inventory of high performing conveyors ideal for warehouse, packaging, parcel handling, and food and beverage manufacturing facilities. Check out our complete conveyor range here .