Understanding the Total Cost of Ownership of Conveyors

Purchasing a conveyor is no ordinary investment, as it requires a considerable amount of capital. This is one of the primary reasons why most business owners spend a lot of time browsing through available options before selecting one that meets their requirements without straining their budget. However, in many cases, buyers fail to include the additional long-term costs which incur besides the price mentioned on the equipment’s invoice.

In this blog, we’ll help you understand what the total cost of ownership of a conveyor is and the steps you can take to keep this cost as low as possible.

Total Cost of Ownership: What’s it all about?

The total cost of ownership of a conveyor (or any equipment) is an accumulation of all direct and indirect costs associated with the purchase of the equipment. In simple words, it’s an estimated sum of all short term and long term operational and maintenance costs of the conveyor. The cost of ownership of any equipment is determined by taking into account parameters such as the initial cost (IC), operational costs (OC) maintenance costs (MC), and useful life (UL).

Controlling Total Cost of Ownership of Conveyors

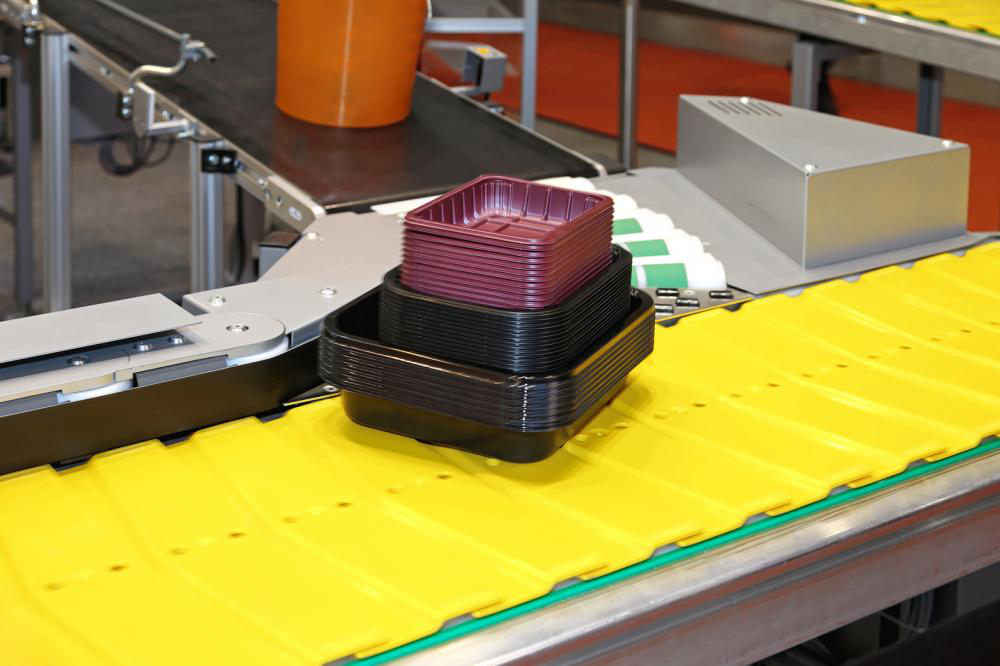

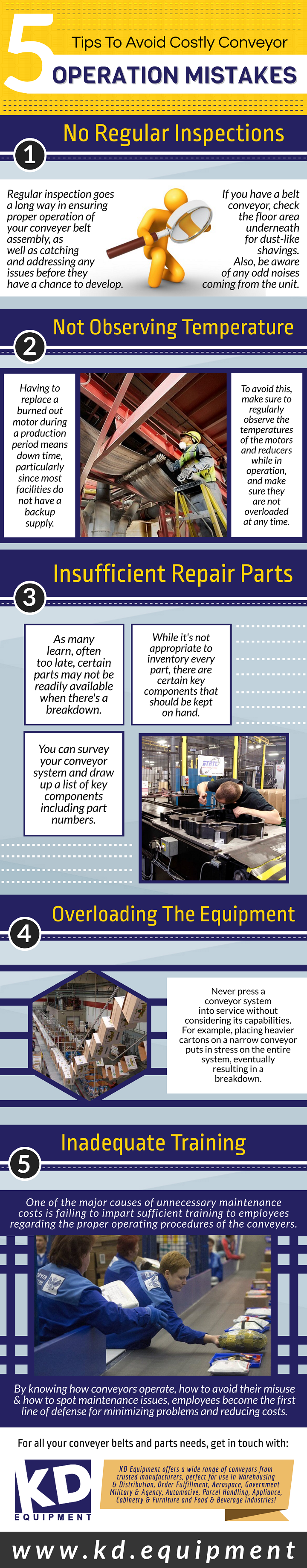

Conveyors belts are complex systems with intricately designed electrical and mechanical parts. Each of these components has a significant impact on the total cost of ownership of these machines. Here are some tips you can follow to keep this cost under control.

Effective Control Configuration

Conveyor belts are equipped with a number of features, most of which can be controlled remotely to cut down on operational costs, which in turn reduces the overall cost of ownership of the belt. When the belt isn’t in use, your operators can switch it off using the automated sleep feature to keep its energy consumption to a minimum.

Boost Power Train Efficiency

Ensure all the elements in your conveyor’s power train are energy efficient. These include the conveyor’s motor, its gear box, and the lubrication used to keep it functioning smoothly. Even a minor decline in energy consumption can lead to a considerable decrease in per annum operational and maintenance costs.

Replace Manual Drive with a Direct Drive

Conveyors with chain and sprocket drive typically require more maintenance in a year than those with a direct drive. Replace your manual drive with a direct drive to lower the total cost of ownership of your conveyor belt.

Interested in purchasing a high-performing conveyor to automate material handling in your facility? Let us help you out!

KD Equipment has been supplying quality conveyor and material handling equipment to commercial and industrial companies in Miami, Sarasota, Tampa and other cities in Florida for more than 3 decades. Our team works tirelessly to ensure that our clients receive handling products manufactured by only the very best in the business. Our extensive range of equipment includes pallet racks, loading dock ramps, dock seals, dock bumpers, air curtains and more.

You can request a quote or find out more about material handling equipmentand storage solutions available on our platform by contacting our representatives at 888-792-9995!