A Handy Conveyor Maintenance Checklist for Facility Owners

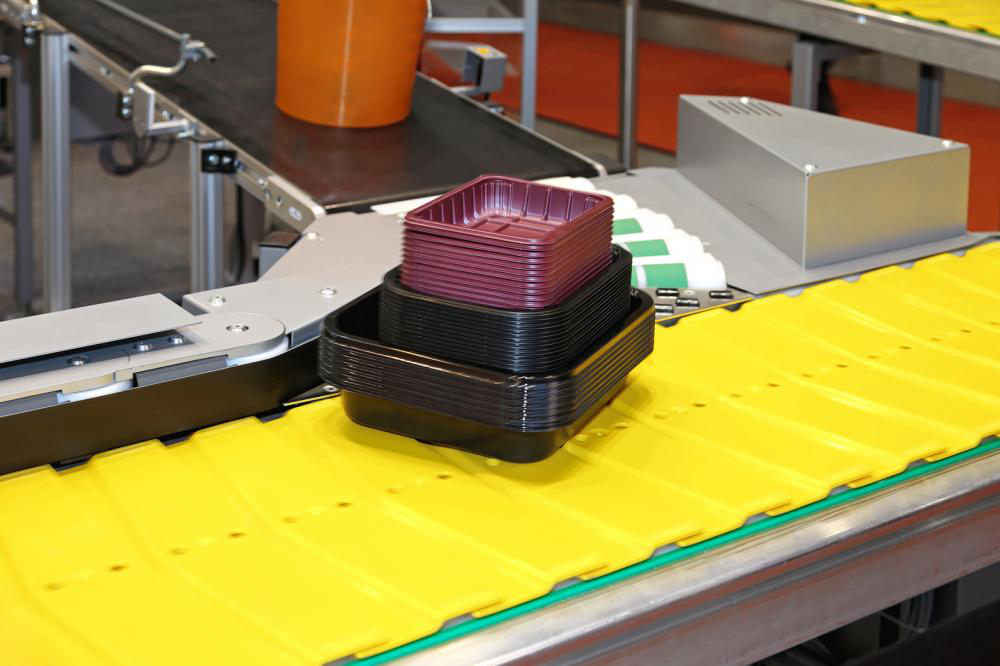

Conveyors have gradually turned into an integral part of warehousing and logistic operations of industrial and commercial set-ups across the globe. With the trend of automation on the rise, more and more companies are installing these belts in their facilities to increase operational efficiency and overall productivity.

Conveyor belts, much like all industrial equipment, need regular inspection and maintenance to continue their operations smoothly. A poorly maintained conveyor is not only a serious safety hazard but it can cause a considerable amount of financial loss to the company in case of a total or partial breakdown.

In this blog, we’ve compiled a comprehensive conveyor maintenance checklist which you can refer to, to ensure that your belt is running in optimum condition at all times.

Daily Check

While most companies hire personnel to thoroughly inspect conveyors, your conveyor’s operator can easily carry out these daily checks. The operator should be required to report:

1.Any visible signs of wear and tear on the body on the conveyor

2.Spillage and debris on or around the belt

3.Improper belt tracking

4.Misplaced safety guards and devices

Monthly Check

Your operator can carry out these inspections as well, but it’s always better to consult professional maintenance experts for monthly maintenance. These experts, with years of experience under their belt, are familiar with the ins and outs of the conveyor; therefore have a far better understanding of all potential safety risks and hazards.

During the monthly inspection of a conveyor, the operator should check:

1.Photo eyes of the equipment

2.Drive torque of hardware

3.The condition of belt’s lacing

4.The turning of rollers

5.Alignment of guard rails

Quarterly Check

Your conveyor’s quarterly inspection should be relatively more comprehensive than those conducted on a daily and monthly basis. Such inspections may require you to halt operations and temporarily shut down the belt, so it can be checked properly. The inspection team should focus on checking:

1.The level of oil in reducers

2.The tension in drive chain

3.The alignment of drive sprocket (if the conveyor isn’t direct drive)

4.The bearing bolts and screws.

The key to having a smooth, problem-free conveyor is to purchase one from a reliable supplier of industrial equipment, such as KD Equipment. We’re proud to be Florida’s leading loading dock equipment and material handling equipment supplier, catering to the needs of commercial and industrial clients based in multiple cities across the state of Florida, including Miami, Jacksonville and Tampa.

Request a quote for high quality conveyorstoday or get in touch with our team at 888-792-9995 to learn more about the solutions we provide.