Conveyor Shopping Pointers for Facility Owners and Managers

Purchasing a conveyor for your facility can be a complex process as there are many variables and specifications to consider. Let’s break the main ones down for you in this post.

Types of conveyor

One of the first things you need to make up your mind on is the type of conveyor you want to purchase.

There are many conveyor options out there in the market. And there are options within those options. Some examples include gravity conveyors, spiral conveyors, chain conveyors, drag conveyors etc.

You must choose a conveyor that best suits your operation. Usually, this depends on your load type, operation environment, facility factors and other factors.

Length of the conveyor

The length of a conveyor is measured in terms of its bed length and overall length.

What is bed length, you ask?

Bed length is basically the amount of conveying surface available on a conveyor. In most cases, the bed length of a conveyor is approximately equal to its overall length. However, where the facility space is limited, even a small difference of length can be big.

When making a purchase, both bed length and overall length of a conveyor should be factored in to make sure the conveyor can work and fit well into the available space.

Width of the conveyor

Just like length, the width of a conveyor is also an important specification. It comes in two dimensions: roller/belt width and overall width.

Choosing a conveyor with the right width is essential to a successful deployment. To specify the right width for your conveyor, consider:

·The dimensions of your widest load

·The amount of side-to-side space available for use

Another key consideration that you must bear in mind when sizing the width for your conveyor is work ergonomics. You don’t want your staff leaning across a running to reach out for an item.

Height of the conveyor

All conveyors should be sized at knuckle height to make it easy for the staff to work. Knuckle height is the vertical distance from the floor to the center of the hand. For an average person, knuckle height is 30 inches.

Note: You can set the conveyor at a lower height depending on how tall your load is.

Speed of the conveyor

The speed of a conveyor is determined by its motor size. Larger the motor size, faster the conveyor speed.

It’s imperative that you specify the right speed for your conveyor. A system too slow can decrease your productivity, while a system too fast can increase chances of errors during work.

Profile of the conveyor

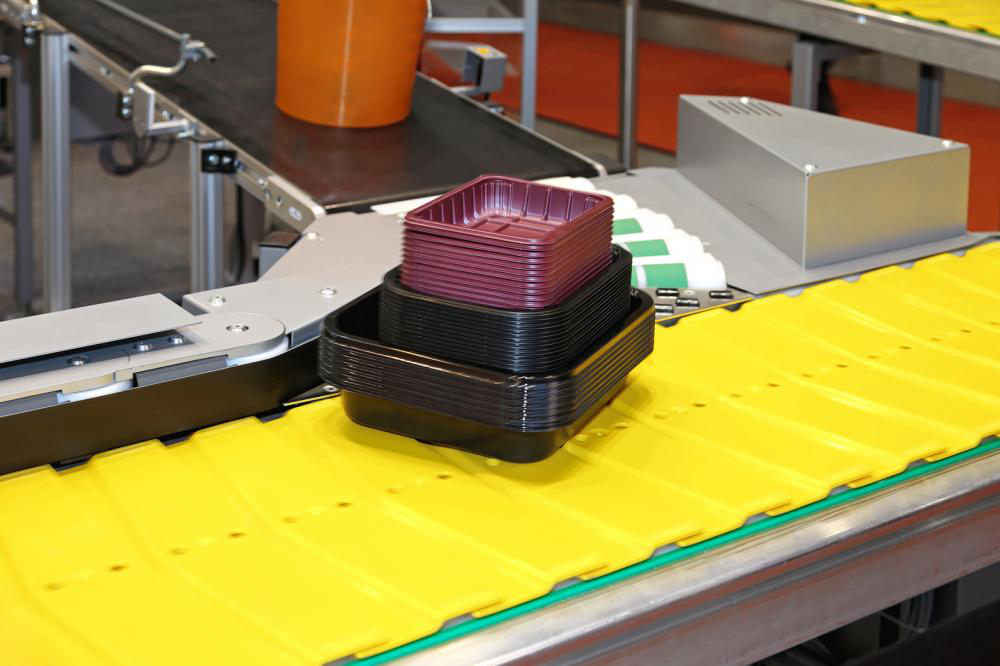

Conveyor come in two profiles: belt and roller. Both profiles have their advantages and specific uses.

For instance, belt conveyors are ideal for handling irregular items and fragile products as they offer greater conveying support to loads. Roller conveyors, on the other hand, are better suited to handling lighter loads. Additionally, you can also use them for package stops or creating diverts on the conveying system.

Choose a conveyor profile that best suits your operation.

Discuss with us

If you can’t decide which conveyoryou should purchase, reach out to us and our experts will be happy to guide you.