How to Increase the Longevity Your Conveyor

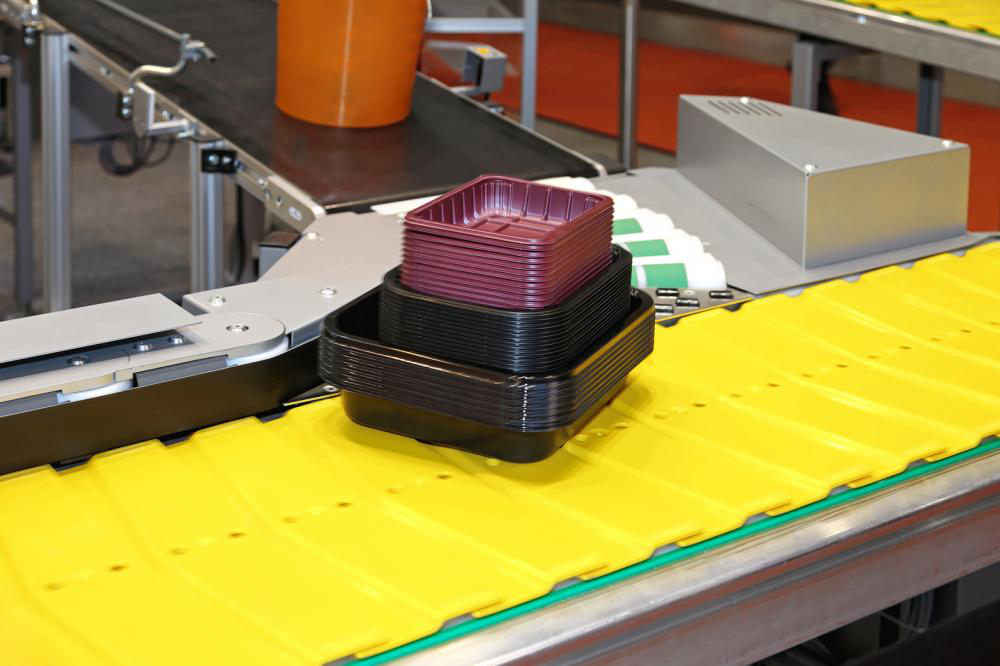

Your conveyor system is the backbone of your facility’s automated processes—it moves products fast, and does so efficiently, while also ensuring employee safety.

However, when a conveyor system slows down, or worse, breaks down completely, your whole production line will come to a screeching halt, costing you resources, time, and ultimately, money.

Operate as intended

Using your conveyor system incorrectly can decrease its lifespan. Be mindful of the following issues when using it:

· The wrong loads: Placing loads that are too heavy or too large on the conveyor can wear down its components. If the load size changes significantly, you may have to alter the conveyor.

· Shock loading: Although dropping loads on the conveyor should be avoided, it is inevitable. You can always shock-load your conveyor, but make sure to understand how the conveyor is loaded or unloaded at different points because shock-loaded conveyors can break down due to increased impact.

· Changing environments: Using your conveyor in an environment it wasn’t designed for leads to accelerated failures—due to chemicals, oils, and contaminants. When re-tasking your old conveyor, make sure you’re aware of the environment it was originally designed for and the new environment you’re going to use it in. Introducing machines that cause airborne debris and dust can impact your conveyor.

· Follow design specifications: For instance, disregarding the drive types and account loads when increasing the speed of your conveyor system may cause its components to get damaged over time.

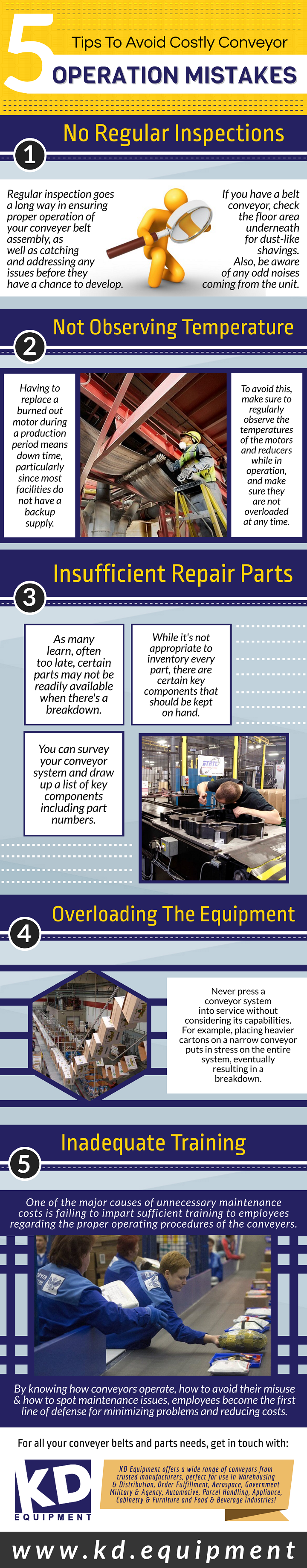

Conveyor maintenance

Make sure your conveyor maintenance is a predictable and designed process. It should be consistent, regular, and scheduled. A well-maintained system performs better, lasts longer, and is safer in the long run.

Make sure to take into account the following stress points in your conveyor maintenance program:

·Connections and belting

·Electrical components of the system

·Investigate noises in the system reported by the staff

·Universal joints, pulleys and bearing should be lubricated

The value of your conveyor maintenance program comes from its predictability. Frequent hands and eyes on the system can help you detect problems and proactively replace damaged or worn-out components. Keep in mind that your conveyor will last longer if you’re consistent and systematic.

Get a wide range of conveyors at KD Equipment!

From belt roller conveyors to line shaft conveyors and gravity rollers, check out our variety of conveyors to pick one that’s exactly right for your operations.

We also provide ergonomics and loading dock equipment for all your warehousing needs and material handling requirements. Contact us for more information.