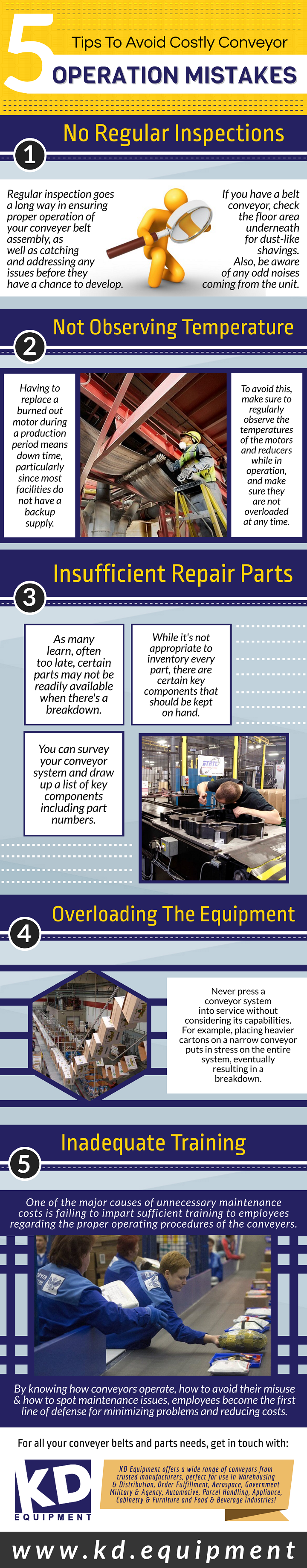

Tips to Prevent Damage in Rack Aisles

Where there are heavy pallets, loading equipment, and people, there’s always the potential for damaged loads. Dented rack frames and damaged pallets are telltale signs of warehouse wear and tear.

So without further ado, hereare some practical methods that can prevent damage to loads, racks, or the facility itself:

Protect the walls behind the racks

Push-through damage is quite common for rack sections that are installed against a facility wall.

You can prevent this by installing floor-level beams at the back of the rack. This preventsthe pallets from touching the back wall. Additionally, floor-level pallet stops can be bolted behind upright frames to block the pallet.

Just make sure that theprotection isn’t loose—it should either be bolted to the floor or installed on the rack system.

Protecting your load beams

In addition to frames, beams are often damaged during loading and unloading. Defective beams can compromise entire rack systems, and spill loads, making them highly unsafe.

When loads are lifted too far up, they can bump against theload beams located right above and dislodge the connectors. Installing locking devices or loading clips is standard practice fora majority of teardrop beam racks. The clips click into place, preventing the beam from dislodging in case the bottom of the beam is bumped during a lifting accident.

Since the clips can snap when the capacity increases, add a bolt to the connections for higher levels of protection. It’s worth mentioning that a rack safety program should check for snapped clips, damage to beams and loosened frame connections.

Protecting palletized loads

Here are some simple techniques that can reduce the issue of damage to loaded pallets:

·Load the pallets correctly. Loads that are off-center or misaligned will put stress on the decking as well as the rack system, damaging them in the process.

·Partial load drops not only cause product damage, but they can also be extremely dangerous to warehouse workers. Make sure to catch falling loads with measures such as wire panels, safety straps or rack safety netting.

·Wrapping pallets stored at high storage positions ensures that the load is less likely to fall.

·Clear aisles and organized racks help workers see the pallets clearly, reducing impact accidents of all types.

One-stop shop for all your warehouse solutions!

With over threedecades of experience under our belt, our material handling company has established itself as a one-stop shop for all your warehousing needs in Tampa, Florida.

From repairing damaged pallet racks to providing a wide range ofergonomics and loading dock equipment , we’re the go-to company for all your material handling requirements. Contact us for more information.